EX-SITU

THERMAL DESORPTION USING GAS THERMAL REMEDIATION

GTR™ is a system that is also used for EX-SITU soil treatment, when the soil is treated on site after excavation (no transportation off site).

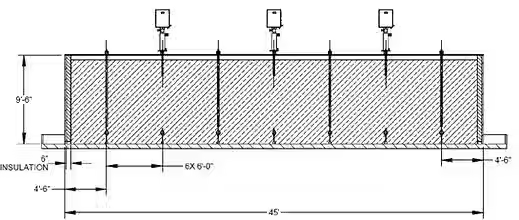

The contaminated soils are excavated and stored in a pile; while building the pile, heating and extraction wells are layered into the soil. On the first layer of contaminated soil, a range of wells is placed. Then again a layer of soil, a range of wells, etc. In a standard design, piles are 65 feet long and between 9 and 21 feet high. The volume of the soil to be treated determines the final width.

In case of large volumes, the number of soil treatment units will be multiplied, and are set up week after week. With such an overlapping setup, large treatment capacities can be achieved with reasonable costs.

EX SITU KEY ADVANTAGES

-

Guaranteed results

-

No soil transportation

-

Easy and flexible

-

Competitive pricing

Batch Pile Treatment is one of the most commonly applied methods of Ex Situ Thermal Desorption for the remediation of soils. When soil is heated, the organic contaminants extracted from the soil pile or are destroyed in place. Concentrations of chlorinated VOCs in soil can be reduced by almost 100% at temperatures much lower than traditional “rotating kiln” arrangements.

Diesel and motor oil range petroleum hydrocarbon and most SVOC contaminants can be removed by 99% or greater, and are most reliably remediated from the soil matrix at temperatures between 200°C to 350°C by the following mechanisms:

-

Steam stripping of NAPLs up to and at 100°C,

-

Evaporation (volatilization) from 100°C to 350°C+,

-

Oxidation from 100°C to 350°C+, and

-

Pyrolysis (thermal decomposition in the absence of oxygen) from 100°C to 350°C+.

Batches ranging in volume from 10,000 m3 to 250 m3 have been successfully implemented in the United States and at several projects in Europe and Africa. Common applications have treated Pesticides, Di- & Trichlorobenzene, Heavy Oils, Paraffins, Dioxins, Jet Fuel, PCE and TCE.

Step-1

Base Preparation

The base area where the batches will be built are levelled for the pile to be constructed upon.

Step-2

Foundational Drainage Layer

A foundational drainage layer of gravel is placed along the base of the pile to isolate the pile from the ground and to drain liquids from the bottom of the pile into the extraction wells. New and/or existing concrete is generally used for the base layer, with slotted steel piping placed as drainage on top of the base layer.

Step-3

Initial Soil Placement

An excavator will pile the dirt onto the batch, one section at a time. Each level is sequentially installed to allow for the heating pipes and SVE pipes to be placed into the pile. A front loader may assist with soil placement.

Step-4

Heating Well Installation (First Layer)

A crane or long-reach excavator places the heating wells onto the dirt after the first layer is formed.

-

Lifting: The crane lifts the pipes using a spreader bar to ensure stability and prevent damage to the wells.

Step-5

Secondary Soil Layering

Once the first row of heating pipes is secured, a new layer of contaminated dirt is placed on top, burying the pipes.

Step-6

Second Heating Well Layer

After the soil is leveled over the first set of pipes, a second layer of heating pipes is installed on top of the new dirt layer.

Step-7

Pile Completion

This process repeats (dirt, pipes, dirt, pipes) until the pile reaches its design height.

-

Workflow: Once one vertical section is complete, the excavator moves backward to begin the next section until the entire batch length is constructed.

Step-8

Insulation and Sheathing

-

Insulation: After construction is complete, insulation materials are placed along the sides and top of the pile to mitigate heat loss to the atmosphere.

-

Sheathing: Finally, a weatherproofing sheathing material is placed over the insulation to prevent rain from entering and cooling the soil.

Containerized Thermal Desorption Systems

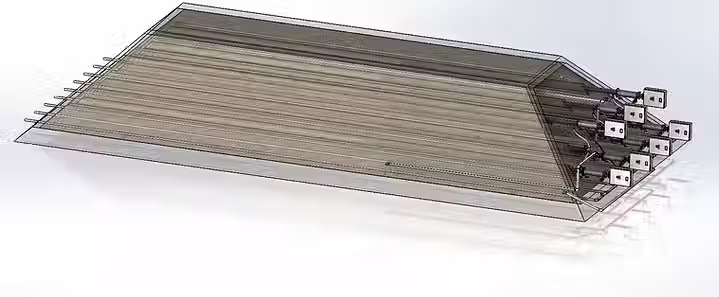

GEO designs, constructs and operates or leases its patented containerized thermal desorption (“CTD”) systems for onsite remediation of contaminated media, including soils, sludge, sediments and mixed waste streams. The CTD systems were designed for crude oil recovery from soils and sludge. The capacity of each container is 80 m3. The units are operated in cycles of 25 or 50 days.

Hydrocarbon Vapor Recovery & Reuse in Thermal Process

The containerized units utilize a vapor recovery and reuse feature that allows the hydrocarbon vapors to be used as a supplemental fuel in a portion of the GTR heater units. This green and sustainable feature reduces the external fuel demand of the project.