Search Results

32 results found with an empty search

- Is In-Situ Gas Thermal Remediation the Key to Successful Soil and Groundwater Remediation in Martinsville, Virginia?

In-Situ Gas Thermal Remediation

- How Does Gas Thermal Remediation (GTR) Compare to Thermal Conduction Heating (TCH) in Phillipsburg, NJ Remediation? - Gas Thermal Remediation and SVE and advanced C3 Vapor Treatment

Gas Thermal Remediation and SVE and advanced C3 Vapor Treatment Thermal Remediation (GTR) Compare to Thermal Conduction Heating (TCH) in Phillipsburg, NJ Remediation

- GTR | Westminster, CA - In-Situ Gas Thermal Remediation

Nestled in the heart of Westminster, California, In-Situ Gas Thermal Remediation is not just a place; it’s an experience that embodies the vibrant spirit of the community. Whether you’re a local or just passing through, GTR is the ultimate destination for those seeking top-notch automotive services and a welcoming atmosphere. Have you ever found yourself amazed by how automotive service can feel? It’s not just about fixing problems; it’s about building relationships and trust. That’s exactly what you’ll find at GTR. With a dedicated team of experts who are passionate about cars and customer service, GTR has become a beloved fixture in Westminster. Customers keep coming back, not only for the quality service but also for the warm, friendly environment. When it comes to automotive needs, GTR covers a broad spectrum. From routine maintenance like oil changes and tire rotations to more complex repairs, GTR is equipped to handle it all. One thing that sets GTR apart is their commitment to transparency. It’s important to them that customers understand the services being performed. You’ll never feel like you’re in the dark or unsure about what’s happening with your vehicle. The knowledgeable staff is always ready to explain and answer any questions you may have. But it’s not just about fixing cars; it’s about enhancing your driving experience. Have you ever considered how just a simple tune-up can improve your vehicle's efficiency? At GTR, they work with you to ensure your car is not only running smoothly but also offering the best performance. They understand that your vehicle is often an extension of yourself, so they treat it with the utmost care. Just imagine pulling up to GTR for a routine service and being greeted by smiling faces and a clean, organized shop. It’s like stepping into a friend’s garage who just happens to be an expert in automotive care. This personal touch is essential in building a strong community, and GTR has perfected it. Now, let’s talk about technology! In today’s world, you want to ensure your vehicle receives the best care possible, and that’s where GTR shines. With the latest diagnostic tools and equipment, they keep up with automotive trends to provide cutting-edge services. Whether you drive a classic beauty or a modern marvel, GTR has the knowledge and tools to ensure your vehicle is treated with the care it deserves. Their skilled technicians are continuously learning, which means you get the best service available. To top it off, GTR is more than just a shop; it’s a hub for car enthusiasts. They often host events, community gatherings, and workshops that bring people together. It’s a place where you can meet like-minded individuals, share your passion for cars, or simply enjoy a cup of coffee while waiting for your vehicle. This sense of community is what keeps GTR thriving in Westminster. In conclusion, if you’re looking for reliable automotive services infused with a sense of community and trust, look no further than GTR in Westminster, CA. Experience the difference of service that genuinely cares about both you and your vehicle. Whether it’s maintenance, repairs, or just a friendly chat about cars, GTR is your go-to destination. So, why wait? Stop by GTR today and become a part of the family! Your vehicle will thank you, and you’ll find yourself returning time and time again.

- GEO Ex-Situ Thermal Remediation Technology (ESTD)

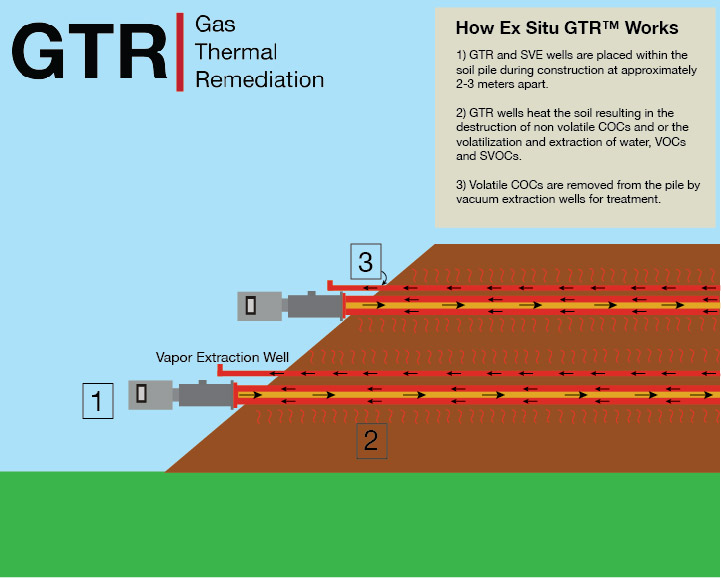

The GEO Ex-Situ Thermal Remediation Desorption (ESTD) Technology is an innovative approach to sludge treatment that combines multi-phase extraction and low-temperature processing within a compact setup to efficiently remove Total Petroleum Hydrocarbons (TPH) from contaminated materials such as sludge. The ESTD technique emphasizes minimizing pre-treatment requirements and reducing secondary pollution, thus improving the environmental footprint compared to traditional remediation methods. By recovering petroleum products directly, ESTD also supports resource reuse, offering a sustainable solution for sludge and soil contamination treatment(GEO Ex-Situ Technology_…). Advantages of ESTD Capacity Improvement : ESTD effectively treats sludge with high oil and water content, overcoming the limitations of other thermal treatment systems that struggle with high-concentration sludge. No Pre-treatment Required : Unlike conventional methods that often require dewatering or volume reduction as pre-treatment steps, ESTD eliminates these requirements, making it versatile for materials of varying sizes and conditions. Complete Vapor Treatment : By employing thorough vapor treatment systems, ESTD ensures minimal emissions, resulting in low exhaust, little smoke, and no ash, addressing common compliance issues and reducing the risk of secondary pollution. Resource Recovery and Reuse : ESTD efficiently extracts and separates oil from sludge, enabling direct reuse, without the need for high-temperature destruction that would otherwise degrade the hydrocarbons. Energy Efficiency and Low Emission : ESTD is designed for energy efficiency, promoting sustainable operations by conserving energy and reducing emissions. This is achieved by using low-maintenance equipment that enhances safety and stability throughout the treatment process(GEO Ex-Situ Technology_…). ESTD Process Overview The ESTD process involves placing contaminated soil or sludge into a constructed pile or pit and applying thermal conductive heating through a series of heating tubes and vapor extraction wells. The treatment proceeds through several key phases: Multi-Phase Extraction (MPE) Before Heating : MPE wells remove mobile oil phases prior to any heating, setting the stage for enhanced subsequent extraction. Initial Heating (80-90°C) : During this phase, non-aqueous phase liquids (NAPLs) are mobilized, and their viscosity is reduced, which enhances solubility and supports contaminant removal using hot water flushing . Steam Stripping (90-110°C) : This phase generates steam to strip TPH effectively, with vapor extraction systems aiding significantly in removing the contaminants. High-Temperature Heating (100-350°C) : Soil permeability is increased through heating, promoting desorption and vaporization of contaminants, which are then removed from the pile. Sustained High-Temperature Maintenance (350-450°C) : The final stage ensures thorough contaminant breakdown , achieving over 99.9% mass reduction (GEO Ex-Situ Technology_…). Comparative Overview of Thermal Treatment Technologies The ESTD approach is benchmarked against several other thermal treatment technologies, including incineration , cement kiln co-processing , pyrolysis , smoldering (STAR) , and soil washing . ESTD's operating temperature range is between 100°C to 350°C , making it more energy-efficient compared to high-temperature treatments like incineration (>1000°C) and cement kiln co-processing (800-1000°C). Moreover, ESTD's ability to treat materials with high TPH and water content without the need for extensive pre-treatment distinguishes it from more conventional methods. Summary of Advantages Over Traditional Technologies : ESTD is more efficient for treating sludge with high oil and water content (>30%), achieving TPH concentrations below 0.1% without high-temperature destruction. Unlike other methods that require considerable pre-treatment , ESTD eliminates such needs, simplifying the process and saving time. It has a significantly lower fuel usage rate (between 8-20 therms per ton) compared to incineration or cement kiln methods, which consume over 30 therms per ton(GEO Ex-Situ Technology_…). Pile Construction for ESTD The construction process for ESTD involves setting up batch piles in cleared, leveled areas. A foundational layer of crushed rock and HDPE sheathing is used to insulate the pile from the ground and to drain liquids effectively. The piles are then built in layers, with heating and Soil Vapor Extraction (SVE) pipes placed at each level to ensure comprehensive thermal treatment and vapor extraction. Insulation is applied to the pile to mitigate heat loss, ensuring efficient treatment. This construction sequence makes ESTD adaptable to various site conditions while ensuring that all necessary infrastructure for thermal desorption is effectively implemented(GEO Ex-Situ Technology_…). Conclusion : The GEO ESTD technology represents a significant evolution in thermal remediation for sludge treatment. By focusing on low-temperature desorption , multi-phase extraction , and recycling of recovered petroleum , ESTD provides an efficient, sustainable alternative to traditional high-energy, high-emission methods. Its robust treatment phases ensure thorough contaminant removal while offering the added benefits of resource recovery and minimal pre-treatment needs, making ESTD a key tool in the arsenal for effective environmental remediation .

- Redwood City, CA Case Study - In-Situ Thermal Remediation

The Redwood City Case Study involves the remediation of a former dry cleaner site located in Redwood City, California , which was contaminated by tetrachloroethylene (PCE) and its degradation byproducts, such as trichloroethylene (TCE) . The contaminated zone covered an area of 384 square feet with PCE concentrations reaching up to 7,100 μg/kg in soils at a depth of 5 feet below ground surface (bgs) . The remediation goals were driven by the need to reduce the risk of vapor intrusion , ensuring that contaminant levels were brought below commercial soil gas screening criteria. The target depth for treatment was 10 feet beneath the building(Redwood City). The GTR© system developed by GEO, in combination with the C3 Technology refrigerated vapor condensation process , was used for In Situ Thermal Remediation (ISTR) . The GTR system effectively heats the contaminated soil and groundwater to target temperatures of 100°C , which allows for the volatilization of PCE. The C3 Technology was then used to condense the vaporized contaminants, achieving >99.9% efficiency in PCE and TCE removal from the vapor stream. This technology helped condense contaminants above ground, avoiding direct release into the atmosphere or absorption by activated carbon, which would eventually require landfill disposal(Redwood City). Technology and Approach : Thermal Conductive Heating (TCH) : The GTR system utilized 9 thermal conductive heating wells placed in a triangular grid pattern across the 384 square feet treatment zone. The wells were powered by 5 GTR+F© heaters , which were fueled by a temporary propane tank system . Auxiliary Fuel Recycling : The GTR+F units have the capability to recycle captured vapors into the GTR unit, utilizing them as auxiliary fuel if the contaminants have fuel value. This design helped reduce overall energy consumption by relying partially on the contaminants as a fuel source. Temperature Control and Monitoring : The system was equipped with 10 thermocouples strategically placed throughout the treatment area to monitor temperature at various distances and depths from the heating wells. A central PLC system was used to monitor and control each heater, ensuring optimal in-situ heating results throughout the 6.5-month treatment period(Redwood City). Results : The remediation successfully achieved the reduction of >99% of PCE contamination in the subsurface soils, meeting all air quality management standards for discharge. The entire process took 6.5 months , after which the remediation goals were met, significantly reducing the potential for vapor intrusion . A notable challenge encountered during the remediation was contamination from a neighboring railroad line , which migrated into the treatment area and necessitated extended heating times. This issue underscored the importance of high-resolution site characterization and establishing clear treatment boundaries(Redwood City). Full Scale Implementation : The GTR system was installed in three overlapping stages to ensure comprehensive coverage of the target zone. The wells were placed in a grid that ensured thorough heating and vapor extraction from the soil. The co-located vapor extraction wells were critical in capturing volatilized contaminants as they were heated, preventing them from escaping into the atmosphere. Conclusion : The Redwood City remediation project demonstrated the effectiveness of the GTR system and C3 Technology in addressing complex PCE contamination at a former dry cleaning site. The use of thermal conductive heating paired with vapor condensation not only achieved the target remediation goals but also minimized secondary pollution by capturing and treating vapors above ground. The recycling of vapors as fuel represents an innovative step toward reducing energy needs and improving overall system efficiency . The lessons learned from managing migrating contamination emphasize the need for thorough site assessments and adaptable treatment plans in dynamic environmental conditions.

- Camp Pendleton Case Study - In-Situ Gas Thermal Remediation

A site showcasing an in-situ gas thermal remediation system, where a network of pipes and equipment is used to treat contaminated soil by heating it on location. Long Summary of Camp Pendleton Case Study - In-Situ Gas Thermal Remediation The Camp Pendleton Case Study focuses on the In-Situ Gas Thermal Remediation (ISTR) of a former fuel storage site located at Marine Corps Base (MCB) Camp Pendleton in Oceanside, California . The treatment zone spanned an area of 4,800 square feet to a depth of 35 feet below ground surface (bgs) , covering areas that included vehicle maintenance and repair facilities, a vehicle painting shop, a wash rack, and a fuel storage station. The site’s lithology consisted of heterogeneous silts, clays, sands, and gravel lenses , which added complexity to the remediation process due to the varied subsurface composition(Camp_Pendleton). Contaminants and Remediation Objectives : The primary contaminants included PCE (tetrachloroethylene) , TCE (trichloroethylene) , vinyl chloride , BTEX compounds (benzene, toluene, ethylbenzene, and xylene) , and naphthalene . The goal was to achieve significant mass removal of these contaminants from both soil and groundwater, with a target temperature of 100°C across the entire subsurface treatment zone(Camp_Pendleton). Remediation Technology and Approach : Thermal Conductive Heating (TCH) was employed using 80 heater wells to uniformly heat the subsurface from the surface down to approximately 40 feet bgs . The wells were powered by natural gas, which facilitated the heating of both soil and groundwater in the target zone. Multiple-Phase Extraction (MPE) Wells : A total of 33 MPE wells were positioned within the thermal treatment zone to serve as the primary extraction points for mobilized contaminants. These wells were complemented by shallow horizontal vacuum extraction points installed in gravel just below the insulating cover to maintain pneumatic control of the uppermost heated zone. Monitoring Systems : Four temperature and pressure monitoring points were strategically placed throughout the site to track the progress of subsurface heating and ensure that the desired temperature was maintained uniformly. The MPE system was operated for 20 days prior to heating to establish hydraulic and pneumatic control before active heating commenced(Camp_Pendleton). Remediation Results : Duration of Heating : The heating phase lasted for 113 days , during which the target temperature of 100°C was reached one week ahead of schedule. This allowed for efficient mobilization and volatilization of the contaminants. Mass Removal Achieved : Over 52,000 pounds of chlorinated and petroleum contaminants were removed from the treatment zone during active heating. Reduction Rates : Average reductions of over 99% were achieved for all target contaminants, including PCE , TCE , vinyl chloride , BTEX compounds , and naphthalene . These results highlight the effectiveness of the ISTR method in significantly reducing contamination levels in both soil and groundwater(Camp_Pendleton). Conclusion : The Camp Pendleton project demonstrates the efficacy of in-situ thermal remediation for complex subsurface contamination involving mixed chlorinated solvents and hydrocarbons. The use of TCH heater wells , MPE systems , and effective monitoring resulted in the comprehensive cleanup of the contaminated zone. The project met its remediation targets efficiently, achieving over 99% mass reduction across all contaminants, with more than 52,000 pounds of pollutants extracted from the soil and groundwater. The success of this project underscores the value of thermal remediation technologies for large-scale, mixed contaminant sites, particularly in challenging geological environments with diverse subsurface compositions.

- Exploring Innovative In-Situ Gas Thermal Remediation and TCH Multi-Phase Extraction and Treatment Techniques in Suzhou, China

Project Overview In a remarkable step for environmental remediation, the Suzhou site in China became the country's first thermal remediation project. This initiative, led by GEO and executed in collaboration with DDBS, demonstrates the capability of thermal technologies to treat hazardous contaminants effectively. With environmental challenges on the rise, this project serves as a beacon for new solutions in cleanup strategies. Location and Duration The project unfolded in Suzhou, a region known for its clay geology and shallow groundwater, situated only 1.5 meters below ground. Over the course of 33 days, a specialized team executed a multi-phase extraction process tailored to tackle severe contamination issues. The swift yet meticulous approach reflected the project’s urgency and complexity. Contaminant Profile The major contaminants identified at this site included benzene, chlorobenzene, Dense Non-Aqueous Phase Liquids (DNAPL), and Total Petroleum Hydrocarbons (TPH-g and TPH-d) commonly found in gasoline and diesel. The project aimed to eradicate over 99% of these harmful substances. This was not just a goal but a reality, showcasing an outstanding success in environmental remediation practices. Site History The site had a long history of industrial use, leading to serious accumulation of hazardous chemicals. This posed significant risks to local ecosystems and public health. Recognizing the critical need for intervention, GEO and DDBS collaborated to explore innovative thermal remediation strategies that could effectively address these dangers. Innovative Techniques The technique selected was In Situ Thermal Remediation, which involved heating the soil to a target temperature of 100°C. This method enhances the volatility of contaminants, allowing them to be extracted efficiently. By applying heat directly to the treatment zone, the project aimed to significantly reduce the risks associated with contaminated groundwater, ensuring the safety of local communities. The Process of In-Situ Gas Thermal Remediation The remediation process began with the installation of thermal wells that introduced heat into the soil layers where contaminants resided. These wells created a subsurface vapor zone that enabled the mobilization and extraction of volatile compounds using multi-phase extraction technology. Phases of Implementation The remediation comprised several critical phases. After setting up the thermal extraction system, operators continuously monitored temperature levels, making adjustments to ensure optimal conditions for successful contaminant extraction. The effectiveness of the method was largely dependent on precise temperature control and constant evaluation of extraction rates. Results The outcomes of this project were impressive, achieving over 99% mass removal of targeted contaminants like benzene and DNAPL. This high level of effectiveness not only highlights the potential of thermal remediation in various contexts but also signifies the innovative approaches necessary to tackle pressing environmental challenges. Visual Insights Thermal extraction well in action during the remediation process. In-Situ Gas Thermal Remediation Lessons Learned Executing the first thermal remediation project in China yielded valuable lessons for future initiatives. A key takeaway was the importance of local community involvement and the need for tailored remediation strategies suited to specific geological and contaminant conditions. Community Involvement Involving local communities throughout the project was crucial. It fostered transparency and built trust, essential elements for the acceptance and success of remediation efforts. By keeping local residents informed, GEO and DDBS ensured that community concerns were addressed, which played a vital role in project sustainability. Future Implications This groundbreaking project not only serves as a benchmark for future remediation efforts in China but also sets the stage for advancements in thermal treatment methodologies worldwide. The results underscore the necessity of innovative strategies to confront complex environmental issues. Scalability of Thermal Remediation As industries expand and more regions face hazardous waste challenges, the adaptability of thermal remediation techniques shines through as a feasible solution for large-scale environmental cleanups. This case study can inspire similar initiatives globally, emphasizing the importance of risk reduction, sustainability, and public health protection. Forward Thinking on Environmental Management The successful multi-phase extraction and thermal treatment of contaminants at the Suzhou site highlights the promise of innovative remediation technologies. The collaboration between GEO and DDBS has sparked a positive narrative for environmental restoration. With the right technologies and community engagement, substantial progress can be made in protecting our planet. Looking ahead, this project not only offers critical insights but also stands as an inspiring model for ongoing and future remediation efforts. By embracing new methodologies and learning from each experience, we can effectively address contamination challenges and work towards creating a cleaner, safer environment for future generations.

- How Does In-Situ Thermal Remediation Effectively Treat TPH-d, TPH-mo, Benzene, Naphthalene, and BaP Contaminants in EPA Region 9, CA?

In the rapidly evolving landscape of environmental remediation, in-situ thermal remediation has emerged as a powerful technique for addressing a range of hazardous contaminants, particularly Total Petroleum Hydrocarbons (TPH), including TPH-d (diesel) and TPH-mo (motor oil), as well as volatile organic compounds like benzene, naphthalene, and benzo(a)pyrene (BaP). In EPA Region 9, California, where environmental regulations are stringent and the consequences of pollution can be severe, understanding the effectiveness of this innovative approach is crucial.In-situ thermal remediation leverages heat to decontaminate soil and groundwater, providing a direct method to address both semi-volatile and volatile organic compounds. By applying thermal energy to contaminated sites, heat can vaporize contaminants, making them easier to extract. This is especially beneficial for heavier hydrocarbons like TPH-d and TPH-mo, which are often resistant to traditional remediation techniques.One of the primary advantages of in-situ thermal remediation is its ability to treat TPH-d and TPH-mo effectively. These compounds, commonly found in areas with a history of industrial activities or petroleum storage, can persist in the environment due to their hydrophobic nature. The application of heat reduces the viscosity of these hydrocarbons, allowing them to migrate towards extraction points. As a result, remediation times are significantly shortened, ensuring faster recovery of affected sites.Moreover, this technique is particularly effective in treating volatile organic compounds such as benzene and naphthalene. Benzene, a known carcinogen, is typically found in areas contaminated by gasoline and industrial solvents. When subjected to elevated temperatures, benzene vaporizes, allowing it to be captured and processed. Naphthalene, frequently associated with mothballs and polycyclic aromatic hydrocarbons, also responds well to thermal treatment. The targeted heating in in-situ thermal remediation enables these contaminants to be efficiently removed from the subsurface environment.Benzo(a)pyrene (BaP) presents another challenge in environmental remediation due to its persistent and toxic nature. This polycyclic aromatic hydrocarbon is often a byproduct of incomplete combustion processes and is associated with various industrial operations. In-situ thermal remediation can significantly enhance the degradation of BaP through thermal desorption, where the heat induces a phase change, making BaP more amenable to extraction or breakdown.In the context of EPA Region 9, California, where regulatory compliance is critical, the use of in-situ thermal remediation is compliant with state guidelines and standards. The technique is not only effective in remediating contaminated sites but also minimizes the disruption to the surrounding environment. This non-invasive approach allows for the restoration of affected areas while ensuring minimal impact on local ecosystems.As environmental concerns continue to gain prominence, integrating advanced technologies like in-situ thermal remediation into remediation strategies is essential for effective treatment of hazardous contaminants. By reducing the levels of TPH-d, TPH-mo, benzene, naphthalene, and BaP, this method plays a crucial role in safeguarding public health and protecting California’s unique ecological landscape.In conclusion, in-situ thermal remediation stands out as a viable and efficient option for treating a wide array of hazardous contaminants in EPA Region 9. With its ability to address both petroleum hydrocarbons and volatile organic compounds effectively, this technique promises faster remediation timelines and compliance with regulatory standards, making it an essential tool in the field of environmental remediation. By prioritizing this innovative approach, we can make significant strides toward a cleaner, healthier environment. Diagram illustrating the Gas Thermal Remediation (GTR) process: High-temperature heat, generated through combustion of fuels like natural gas, circulates to heat soil and groundwater to 100-400°C for contaminant removal, with vapors extracted and treated through a specialized system.

- How Can SVE and Advanced C3 Vapor Treatment Help in Andover, MN with Contaminants like Petroleum Hydrocarbons and Chlorinated Compounds?

SVE and Advanced C3 Vapor Treatment

- Exploring the Effectiveness of GEO Vapor Treatment: Tonawanda, NY Case Studies with SVE and Advanced C3 Vapor Treatment

SVE and Advanced C3 Vapor Treatment